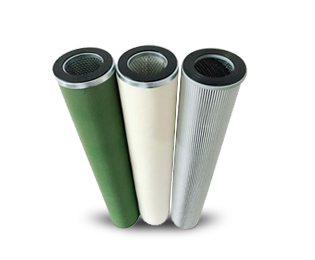

Product Introduction:

The Filter Separator Cartridge represents a groundbreaking leap in filtration technology, meticulously engineered to deliver unmatched performance in separating liquid from gas or other liquids. With its cutting-edge design and exceptional filtration capabilities, it has become an indispensable asset across industries where purity and separation are of paramount importance.

Application Scenarios:

The versatility of Filter Separator Cartridges extends across a multitude of scenarios, including:

1. Oil and Gas Industry: These cartridges are pivotal in ensuring the purity of gases used in oil and gas processing, preventing contamination and safeguarding equipment integrity.

2. Aerospace: Filter Separator Cartridges are critical in aviation, where they ensure the purity of aviation fuel, enhancing engine performance and flight safety.

3. Chemical Processing: In chemical manufacturing, these filters are indispensable for separating different liquid phases during processes, enhancing product quality and yield.

4. Pharmaceuticals: Filter Separator Cartridges play a vital role in maintaining the purity of gases used in pharmaceutical manufacturing, meeting rigorous quality standards.

5. Marine: In marine applications, these cartridges are employed to purify fuel and oil, preventing engine damage and ensuring smooth operations.

Product Advantages:

Filter Separator Cartridges offer an array of advantages:

1. Exceptional Efficiency: Their advanced design ensures superior separation of liquids from gases, removing even the smallest droplets.

2. Cost Savings: By preventing contamination and equipment damage, these cartridges reduce maintenance costs and minimize downtime.

3. Compact Design: Filter Separator Cartridges are space-efficient, making them suitable for various installation environments.

4. Customization: Tailoring cartridges to meet specific industry and application requirements for optimal filtration performance.

Working Principles:

Filter Separator Cartridges operate based on advanced separation principles:

1. Filtration Media: The cartridge contains specialized filtration media that capture liquid droplets as gases pass through.

2. Coalescence: Small liquid droplets merge to form larger ones, facilitating efficient removal from the gas or liquid phase.

3. Gravity Separation: Larger liquid droplets are separated from the gas or liquid phase, typically through gravity, and collected for removal.

Future Development:

The future of Filter Separator Cartridges holds exciting prospects for innovation:

1. Advanced Materials: Ongoing research aims to develop novel filtration materials with enhanced separation efficiency and longevity.

2. Smart Filtration: Integration of sensors and IoT technology for real-time monitoring of cartridge performance and predictive maintenance.

3. Sustainability: Innovations in materials and processes to make filtration more eco-friendly and sustainable.

Conclusion:

The Filter Separator Cartridge is a testament to the relentless pursuit of efficiency and effectiveness in filtration technology. Its exceptional efficiency, cost-saving benefits, and compact design make it the preferred choice in industries where liquid and gas separation is pivotal. As technology continues to advance, Filter Separator Cartridges will remain at the forefront of filtration, ensuring the integrity and quality of gases and liquids in critical processes, contributing to enhanced productivity and sustainability.