Optimizing Natural Gas Filtration with Coalescing Elements

Introduction

Natural gas, a versatile and efficient energy source, serves as a cornerstone of various industrial and residential applications. To maintain the purity and quality of natural gas, robust filtration systems are a prerequisite. This article delves into the importance of coalescing filter elements in natural gas filtration while avoiding specific brand references.

Foundations of Natural Gas Filtration

Filtration is an inherent component of natural gas processing, impacting industries such as energy production and manufacturing. The objective is to eliminate impurities, like solid particles and liquid droplets, from the gas stream. This purification process ensures the gas meets industry standards and safeguards downstream equipment.

The Crucial Role of Coalescing Filter Elements

Coalescing filter elements are pivotal to natural gas filtration systems. Their principal purpose is to enable the coalescence of minute liquid droplets into larger, more manageable forms. This coalescing process significantly contributes to improving gas quality, reducing maintenance needs, and optimizing equipment performance within the natural gas sector.

The Unique Contribution of Coalescing Dehydration Filter Elements

Moisture in natural gas processes, often originating from condensation and water vapor, is a recurring challenge. Coalescing dehydration filter elements are specially designed to address this issue, effectively eliminating moisture and preserving gas dryness. This dual functionality ensures equipment protection, operational efficiency, and enhanced natural gas quality.

The Expertise of Coalescing Filter Manufacturers

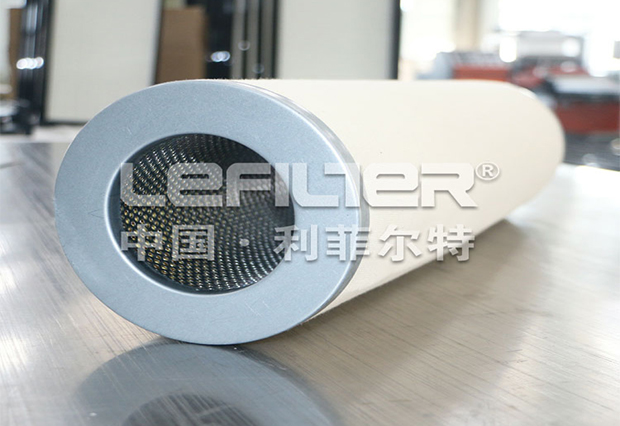

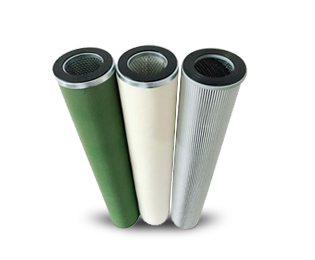

Coalescing filter elements undergo precise engineering to meet the rigorous demands of the natural gas industry. They incorporate advanced filtration media, robust components, and meticulously engineered casings. Exceptional quality and precision define these elements, making them highly efficient in various natural gas applications.

Elevating Natural Gas Filtration with Coalescing Elements

Coalescing filter elements have played a transformative role in enhancing the efficiency and effectiveness of natural gas filtration across multiple sectors. Their capacity to separate liquid contaminants, such as oil and water, from natural gas streams results in cleaner gases adhering to stringent industry standards. Furthermore, these elements contribute to reducing maintenance and operational costs, ultimately improving operational efficiency, which is crucial for the reliability and sustainability of the natural gas industry.

The Value of Coalescing Element Replacements

Coalescing filter element replacements are indispensable for applications requiring moisture and liquid contaminant removal while ensuring equipment operates efficiently. They provide cost-effective solutions for gas processing, prioritizing performance over specific brand names. These replacements are engineered with precision and serve as a critical component in achieving cleaner and higher-quality natural gas.

Conclusion

Coalescing filter elements are a cornerstone of the natural gas processing industry due to their capacity to efficiently remove liquid contaminants and moisture from gas streams, thereby ensuring the dependability and quality of various industrial processes. Coalescing dehydration filter elements offer crucial moisture control, equipment protection, and operational efficiency enhancements. Through precision manufacturing and unwavering commitment to quality, coalescing filter elements empower industries to work with cleaner gases, reduce maintenance demands, and enhance operational efficiency. Natural gas filter element replacements provide the same precision and quality, offering a reliable avenue for effective gas filtration.