In the world of power generation, maintaining optimal system performance and efficiency is of paramount importance. The Power Plant Condensate Water Filter and Power Plant Condensate Water Filter Cartridge play a pivotal role in achieving these objectives. Here's a deep dive into these innovative technologies that are reshaping the face of energy production.

1. A New Era in Power Generation: The Power Plant Condensate Water Filter and Cartridge

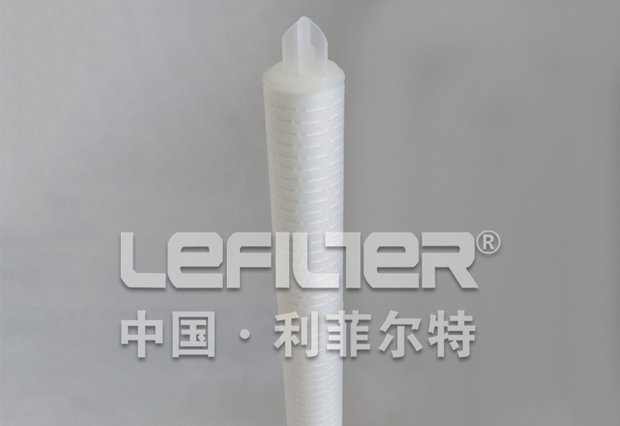

The Power Plant Condensate Water Filter and its counterpart, the Power Plant Condensate Water Filter Cartridge, are key innovations in the energy sector. These filter systems are specially designed to efficiently purify condensate water in power plants, removing impurities and contaminants that could hinder the efficiency and longevity of the plant's machinery.

2. The Power of Purification: Diverse Application Scenarios

The Power Plant Condensate Water Filter and Cartridge have found wide-ranging applications in power plants around the globe. Their high efficiency and reliability make them ideal for use in power plants of various types, including fossil fuel power plants, nuclear power plants, and thermal power stations. Their use contributes to the overall system efficiency, helping to extend the service life of equipment, reduce downtime, and enhance energy production.

3. Rising Above Challenges: The Key Advantages

These filter systems come with an array of advantages. They offer high filtration precision, superior flow rates, and outstanding durability. Their ability to remove impurities down to the microscopic level, including rust, dirt, scale, and other particulates, makes them indispensable in power generation. Plus, they are cost-effective, easy to replace, and highly resistant to varying pressure and temperature conditions commonly encountered in power plants.

4. Harnessing the Power of Advanced Filtration: The Working Principles

The Power Plant Condensate Water Filter and Cartridge operate based on the principle of mechanical filtration. As condensate water passes through the filter media, the physical barrier provided by the filter removes impurities. The pleated design of these filters enhances their surface area, allowing for more efficient filtration without compromising on the flow rate.

Technical parameters

Specification

Tomorrow's Titans: The Power Plant Condensate Water Filter and Cartridge

As the world is becoming increasingly conscious about energy efficiency and environmental conservation, the role of the Power Plant Condensate Water Filter and Cartridge is set to become even more crucial. These filtration systems are already a keystone in the sector, with their impressive capacity to purify condensate water, improving system efficiency, and prolonging machinery lifespan. The future is likely to witness these systems take center stage in power generation facilities across the globe.

2. The Expanding Horizon: New Application Scenarios

With the rise of renewable energy sources and the progression towards greener power generation methods, the application scenarios for these filters are expected to expand. They could potentially find use in upcoming clean energy power plants, including advanced solar thermal facilities, biomass plants, and others. Their high efficiency and reliability will undoubtedly play a vital role in the functionality and efficiency of these future power plants.

3. Rising to the Challenge: Product Advantages in the Future

The future will see a greater push towards sustainable and cost-effective solutions in power generation. The Power Plant Condensate Water Filter and Cartridge, with their superior filtration precision, high flow rates, exceptional durability, and cost-effectiveness, will be in even greater demand. Improvements in the design and material science behind these filters can further enhance their resilience and longevity, offering more significant benefits to the power generation industry.

4. Advancing Innovation: Evolving Working Principles

While these filters currently work on the principle of mechanical filtration, future advancements could integrate novel technologies to further improve filtration efficiency. The integration of nanotechnology, for instance, could allow for the removal of even smaller contaminants. Similarly, advancements in material science could lead to more robust and durable filter materials, further enhancing their effectiveness and lifespan.

In conclusion, the Power Plant Condensate Water Filter and Power Plant Condensate Water Filter Cartridge are not merely pivotal pieces of today's power generation puzzle, but they hold promise for tomorrow's energy landscape. As we charge forward into a future shaped by the twin imperatives of efficiency and sustainability, these advanced filtration systems will undoubtedly continue to play a key role in how we generate power, ensuring cleaner, safer, and more efficient energy for all.

FAQ

Q: How does fluid viscosity affect the performance of a high flow filter element?

A: The viscosity of a fluid affects its flow rate and the pressure drop across the filter. Higher viscosity fluids will flow slower and cause a larger pressure drop, which can impact the performance of a high flow filter element.

Q: Can high flow filter elements be used to filter out viruses?

A: Most high flow filter elements are not rated to filter out viruses due to their small size. Specialized ultrafiltration or nanofiltration filters would typically be needed for virus removal.

Q: How does a high flow filter element help in reducing system downtime?

A: High flow filter elements can reduce system downtime by extending the interval between filter replacements due to their large filtration area and capacity. However, regular monitoring of pressure drop and flow rate is still necessary.