Introduction

As we push the boundaries of technological advancements in water purification, Power Plant Condensate Water Filters and their corresponding Filter Cartridges are pioneering solutions uniquely tailored for the power generation industry. They symbolize innovative water filtration, delivering unparalleled operational performance in challenging power plant environments. We offer an in-depth exploration of these vital products, encompassing their introduction, application scenarios, advantages, and working principles.

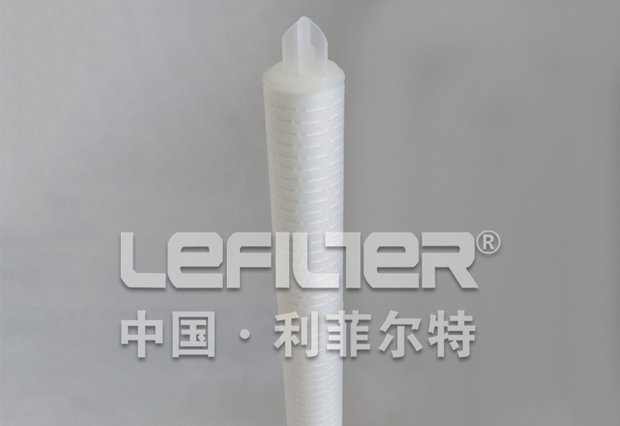

The Power Plant Condensate Water Filter and its corresponding Filter Cartridge are cutting-edge filtration devices engineered explicitly for power plant applications. Crafted with precision and durability in mind, they play an instrumental role in ensuring the uninterrupted operation of power plants, contributing significantly to their productivity and efficiency.

Technical Parameters

| Filter Media | Polypropylene(PP) |

| Length | 20"(508mm), 40"(1016mm), 60"1524mm) |

| Outside Diameter | 6 inch (152mm) |

| Inside Diameter | 3.5inch(89mm) |

| Filtration Rating | lμm, 2μm,3μm, 5μm,10μm, 20μm, 40μm,70μm,100μm |

| Support/Drainage | Polypropylene (PP) |

| End Cap Material | Glass fiber reinforced Polypropylene (PP) |

| Outside | Netting, Cage |

| Seal Material | EPDM, Buna-N, Viton |

| MaximumOperating Temperature | 82°C |

| Maximum Differential Pressure | 3.4Bar at 82°C |

| Suggested Maximum Flow Rate | 20"(508mm)-30m³/h

40"(1016mm)-50m³/h

60"(1524mm)- 70m³/h |

Application Scenario

These products have found their niche in power plants, particularly in the purification of condensate water, a critical component in power generation processes. This application is crucial for maintaining the quality of the steam, maximizing turbine efficiency, and ensuring the longevity of the power plant's equipment.

Product Advantages

The Power Plant Condensate Water Filter and Filter Cartridge present an array of compelling advantages. They offer superior filtration performance, effectively removing impurities and reducing the risk of equipment fouling and scaling. With a high dirt-holding capacity and excellent flow rate, these filters ensure efficient operation while minimizing maintenance downtime.

Moreover, their robust construction ensures high endurance, suitable for the demanding conditions of power plants. The use of these filters and cartridges results in significant savings on maintenance and equipment replacement costs, making them a cost-effective choice for power plants.

Working Principles

The operation of the Power Plant Condensate Water Filter and Filter Cartridge is grounded on a simple yet effective principle. As the condensate water flows through the filter, impurities are trapped within the filter media. The pleated design of the cartridge maximizes the filtration surface, leading to enhanced filtration efficiency and longer cartridge life.

Conclusion

In a nutshell, the Power Plant Condensate Water Filter and its associated Filter Cartridge are indispensable components of the modern power plant infrastructure. With their superior performance, broad applicability, and multitude of benefits, they provide an optimal solution to the industry's pressing need for reliable, high-performance filtration systems. As such, they are set to reshape the future of water purification within the power generation sector, elevating standards and redefining industry benchmarks.

FAQ

Q: What is a pre-filter and why would I use one with a high flow filter element?

A: A pre-filter is used to remove larger particles before fluid reaches the main filter, helping to extend the life of the main filter. In a high flow system, a pre-filter can help manage the load on the main high flow filter element.

Q: How does the filter housing affect the performance of the high flow filter element?

A: The filter housing directs the flow of fluid and maintains the pressure in the system. A properly designed housing ensures that fluid evenly flows through the high flow filter element, maximizing its efficiency.